SealOE

HOME | BRANDS | AP Services | sealOE™

SealOE™

Yarway Model 5500 small globe valves have an extremely large packing cross-section due to their bonnet-less design. This typically requires a compromise of either ease of cycling or leak-free service. The standard packing set for small Yarway globe valves includes a six ring set yielding an expected packing drag of ~960 lbf under 4,000 psi packing stress. A reengineered packing set will decrease stem friction while maintaining sealability.

View full case study

Edwards Model 848Y small globe valves were initially manufactured with extremely deep stuffing boxes with room for 8 rings of packing. In order to remain leak free the 8 rings of packing needed tremendous stud torque often rendering the valve inoperable.

View full case study

Retrofit of a Graphite Pressure Seal may not work in all applications. For certain Borg Warner designs, a modfication of the bonnet is necessary.

View full case study

Borg Warner small globe valves which have a single large threaded gland are difficult to pack without damaging the packing due to the threads. The single gland requires the proper torque to obtain sealing

View full case study

For proper transmission of torque to the fluid sealing product, be it valve packing or gasket, a hardened washer should be a requirement

View full case study

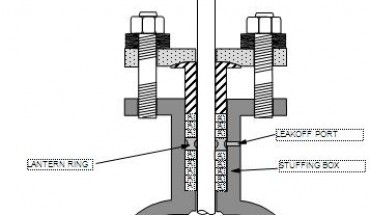

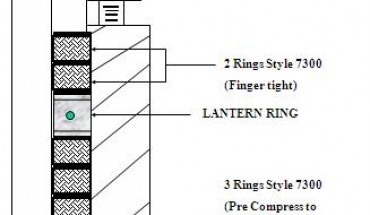

Many old plant designs include the use of "lantern" ring to leak-off detection system on double packed valves. Metal lanterns can cause stem damage, are difficult to remove and can corrode into the stuffing box

View full case study

Many times unpacking a valve can be extremely diffult, time consuming and in the end may even cause damage to the valve stem. Hydrolazers can be used effectively to same time, money, and even reduce radiation dose.

View full case study

Chronic cover gasket bonnet leaks have occurred on Westinghouse check valves

View full case study

Sites experience "chronic" packing leaks due to the installed condition of the equipment. The addition of graphite washers to a standard graphite or braided packing set can significantly improve performance.

View full case study

Severe stem galling can be caused by cocked packing gland on many valve designs.

View full case study

Small Masoneilan Model Varipack 2800 valves have had chronic valve packing leaks. Due to the unique and limited size of the valve air operator, very little packing load can be accommodated. Valve is typically intended for low temperature service and in applications where the valve packing can be easily attended to. If installed in high temperature, remote/inaccessible locations special attention to valve packing selection is necessary to obtain “leak-free” service.

View full case study

Typically Bleeder Trip/Non Return Extraction Steam Check Valves are required to meet “free swing” requirements to insure the main turbine is adequately protected. To meet this “free swing” requirement of the disc requires that valve packing loads are light and DO NOT prevent “free swing”. Typically in the compromise to achieve “free swing”, the packing leaks.

View full case study

Some sites have noted some crumbling or damage to the carbon bushings used to take up the extra space in a stuffing box when using the standard 4-5 rings of valve packing.

View full case study

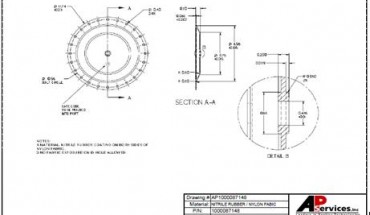

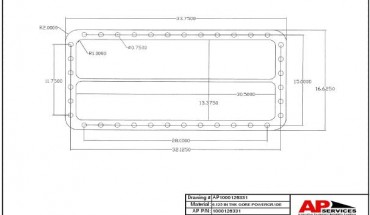

Material for Water Proof Door Seal is difficult and expensive to obtain. Through reverse engineering, the identical material can be readily and economically supplied.

View full case study

Reverse Engineering of the PTFE chevron valve packing provided for BWR Scram Inlet & Outlet valves provides the same material at an economical price and favorable delivery.

View full case study

Positioner Cam for Air Operated Valve no longer available. Reverse Engineer can provide a path forward to obsolete parts no longer being supplied

View full case study

Air Operated Valve Diaphragms are difficult, expensive and hard to obtain at times.

View full case study

To get ahead of valve packing leaks, at times, requires an investment in repacking the “chronic” valve packing leakers and to address the issue proactively. Too often crews are unfamiliar, inefficient and unskilled in the methods of valve packing.

View full case study

Typical agitator packing of Kevlar/Teflon does not perform. Using improved packing material can significantly improve this “chronic” problem area.

View full case study

Valve packing which contains PTFE when installed in Bleeder Trip (BTV)/Non-Return Check valves can be subjected to accelerated corrosion due to the application.

View full case study

Condensate Pump Discharge flange gasket failure (Style CG), due to radial buckling.

View full case study

Door Seals on Absorber Scrubbers are very challenging due to the extremely corrosive environment. OEM supplied Viton dovetailed gaskets leaked at several locations. Garlock was able to make a one piece gasket thru their welding (fusing) process which was faced with Gore-Tex joint sealant.

View full case study

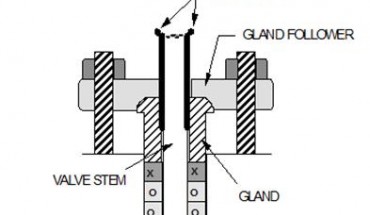

Valve manufacturers typically intend that their valves be installed with the stem in the vertical direction, but due to space and location, these valves are installed with stems horizontal. Particularly on large valves (i.e. >12”), the weight of the operator and stem tend to droop, causing not only excessive lateral loading on the valve packing but in severe cases can cause stem galling by contacting on the back seat or gland follower. Installation of tight clearance hardened carbon bushings can provide adequate stem support, to relieve the lateral stress on valve packing and insure the stem does not contact metal valve parts (i.e. backseat, gland).

View full case study

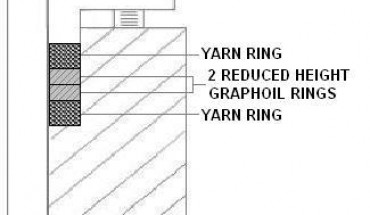

Traditionally die formed graphite rings (i.e. Style 6300) are manufactured as square rings, but when stuffing box depth is limited or lower packing frictions are required in a pure graphite packing system, reduced height die formed rings (i.e. rectangular less height then width) can still provide “leak-free” service and met these additional restraints.

View full case study

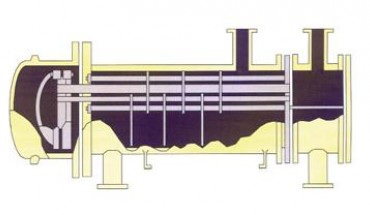

Main Generator Hydrogen Coolers typically experience cooling water leaks due to a combination of design which used inexpensive simple rubber gaskets, less than stellar sealing surfaces, lack of adequate bolting and in-service degradation of the sealing surfaces. The use of expanded PTFE gasket material with improved bolting procedures has successfully eliminated these leaks at numerous stations.

View full case study

Accelerated oxidation of graphite can occur at temperatures above 650 degrees F, which leads to severe steam leaks. The replacement of graphite with Thermiculite faced or filled gaskets has eliminated these leaks.

View full case study

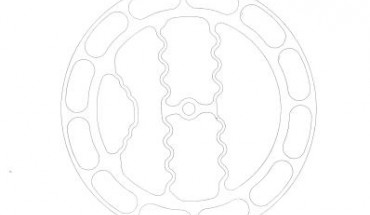

OEM supplied gaskets for High Voltage Bushing Box Gasket applications have had a history of leaking due to the poor sealing ability of the original Cork/Neoprene gasket provided. A lack of good sealing surfaces and limiting bolting load available caused even Garlock Style 3200 gaskets to fail. Upgrading to an expanded PTFE (ePTFE) gasket with a reduced gasket surface area successfully sealed the application.

View full case study

At the #2 Bearing Oil Drain flange on a common gas turbine, hot air at 700°F and 180 psi pressure blew out a simple flexible graphite sheet gasket. Change out is extremely difficult, costly and time consuming (6 days). With the use of a Kammprofile gasket, improved sealing was obtained along with quicker installation (6 hours).

View full case study

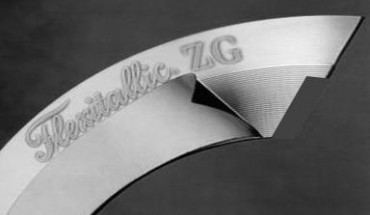

Spiral Wound gaskets made from 316SS winding with graphite filler were buckled and pieces were found in the turbine. Gasket was converted to a spiral wound with the addition of an inner retaining ring.

View full case study

Typical 316SS Spiral Wound Gaskets do not provide adequate gasket recovery properties for specific situations. Improved sealing due to increased recovery can be obtained by upgrading to a Heat Treated Inconel X-750 winding material in lieu of the more standard 316SS.

View full case study

Boiler manway doors may not be centered due to wear on the hinges or difficulty in assembly, so there may be an excessive gap in one quadrant which allows the gasket to extrude, possibly springing apart and resulting in leakage. A Flexitallic Style MCS gasket has a centering guide that permits the gasket to assume its correct position and to compensate for inequalities in plate contours as well as to prevent shouldering and pinching caused by radial misplacement.

View full case study

Gland Seal Casing, Rotor Gland Joint was at 20 psi to full vacuum at 500°F was leaking with a simple gasket of 1/16” thick soft iron, dove-tailed due to size and design. Replacement with a special designed segmented Kammprofile has been successfully in service since 2006.

View full case study

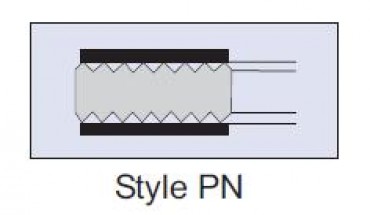

A high pressure heater with tongue & groove flanges which had no built-in compression stop used a Style R Spiral Wound (very narrow gasket). This design caused the gasket to be over-compressed; additionally it was hard to remove the over-compressed gasket from the groove. The goal was to minimize the radiation exposure during maintenance and provide improved sealing. The solution was a Flextitallic Style PN Flexpro Gasket.

View full case study

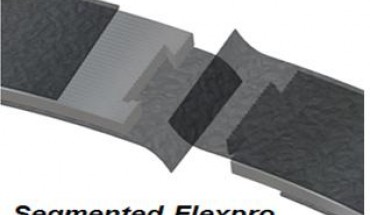

A Residual Heat Removal (RHR) heat exchanger required a gasket change out, but surrounding structures prevented removal of the tube bundle, which would have made traditional change-out, extremely difficult, costly and time consuming. The use of a segmented Flexpro gasket provided a quicker, easier installation.

View full case study

In Limitorque Motor Operators with time the oil separates from the grease causing nagging oil leaks, due to weeping of the oil and the inadequate sealing stress typically provided. ePTFE gaskets require lower stresses to seal and stops the oil weeping, preventing these oil leaks.

View full case study

Due to inadequate load on the OEM spiral wound gasket persistent leaks occurred. By calling out a low stress spiral wound gasket with inner/outer rings and reducing the gasket width to increase the gasket load, leak-free service was achieved.

View full case study

The combination of stem misalignment, high packing friction, and frequent valve cycling can cause valve performance problems in Feed Reg Valves.

View full case study

The use of graphite packing in Fisher heater level control valves and feed regulating valves can cause “sticktion” during valve stem cycling leading to valve performance issues. This can be eliminated by switching to Style 5718 ePTFE jacketed seal rings with Style 5000 end rings.

View full case study

Original specified fiber gaskets do not provide reliable sealing on lube oil skid flanges. Converting to new generation gasket materials that seal oil without weeping is recommended.

View full case study

OEM supplied bonnet gasket on Class 150# and 300# Crane Gate Valves is typically a thin corrugated metal gasket. As these valves age, the flange face surfaces deteriorate over time and create sealing problems when attempting to use these type gaskets. The solution is to use a flexible graphite sheet gasket or a graphite faced metal gasket. The graphite provides a far superior sealing surface due to its ability to flow into flange imperfections.

View full case study

Valve bonnet designs that utilize male/female flanges with a spiral wound Style R gasket are at risk for gasket failure, especially on higher pressure systems. The lack of containment on the inner diameter of the gasket has resulted in inward buckling of the spiral wound gasket. Upgrading to Style RIR spiral wound gasket can prevent this from occurring.

View full case study

Valves with active leak-off that require a double set of packing are difficult to seal. Optimize the packing set by reducing the number of rings and increasing gland load, and install a carbon lantern ring to replace the metal lantern ring to eliminate stem scoring.

View full case study

It has been observed that chronic packing leaks have occurred on double disc gate valves in safety injection and charging systems in PWRs. This leakage of boric acid typically is occurring around the gland follower O.D, and was determined to be caused by excessive gland follower clearances and stuffing boxes oversized by 0.008”-0.020”. A simple solution is to utilize a tight tolerance high density carbon bushing above the packing set.

View full case study

Often the primary air pushed through the heater baskets on the air heater air outlet is considered to be “clean”. In reality, there is fine particulate that clings to the baskets and as the primary air passes through it pushes the dust into the ducts downstream. The dust collects in the low spots and eventually packs in tight enough to rupture expansion joints. The original OEM supplier failed to recognize the potential hazards for this application, and the joint became the cause of several un-planned outages.

View full case study

The existing expansion joint on an air transfer duct failed prematurely due to oil laced water collecting at the bottom of the joint. The weight of water restricted the movements which caused the expansion joint to tear at the corners. Holz Rubber solved the problem by molding a galvanized drain into the bottom of the joint.

View full case study

The existing expansion joints for the re-heat duct in a Gas Turbine were failing prematurely due to the fact they were not designed for the severe lateral movements and high temperatures (1300 Deg F). Holz was able to re-engineer the joints specifically for this unique application.

View full case study

A&E specified a potential temperature excursion as the primary design parameter. High temperature composite materials were necessary to meet specified design temps and as a result “wicked” and held moisture. This expansion joint was a constant source of leaks and eventually failed many years ahead of typical life expectancy.

View full case study

RTO Outlet takes reduced temperature gases (1500 deg F top) down to 400 deg F at a cement plant. The existing expansion joint failed prematurely due to breakdown of the reinforcement. Several problems were also noted.

View full case study

Exposed Inconel wire jacket from flexible graphite wire reinforced packing rings wedged between the valve body and stem was pulled into the flow stream and caused stem scoring damage.

View full case study

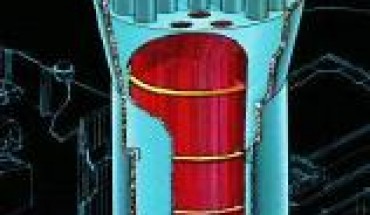

The replacement of a pressure seal gasket can be one of the most frustrating maintenance jobs around. The success ratio of a metal pressure seal tends to decline with the age of the valve and can be attributed to the valve condition.

View full case study

Numerous packing failures occurred on the Ash Grinders at a coal fired power plant in Texas. Original design included an OEM braided material with a lantern ring installed. Packing failure led to weekly maintenance of cleaning out the pits and repacking and injecting them a sealant/lubricant that cost the plant over $800.00 per 5 gallon container. AP Services engineered a proven packing configuration for this application that resulted in no leakage.

View full case study

Current Impro air seal installed on clinker grinders at a coal plant in Pennsylvania failed due to extreme rigors of the clinker grinder system. AP Services designed a special packing set that replaced the expensive Impro Seal and eliminated leakage on these clinker grinders.

View full case study

OEM Packing used in Condensate Pumps at a BWR nuclear plant had uncontrollable leakage. AP Services recommended a new material and installation practice resulting in very minimal leakage and unprecedented longevity while still allowing the pump shaft to run cool.

View full case study

Previous packing installed on Nuclear Charging Pumps resulted in excessive leakage and failure after only 1500 hours in service. Specifically designed Garlock Charging Pump Packing greatly reduced leakage and increased service life.

View full case study

A high cycling heat exchanger experienced flange leakage with the use of a kammprofile style gasket. A spiral wound with heat treated Inconel X-750 was recommended for its outstanding ability to recover under harsh cyclic conditions. This unique winding provided the extra resiliency needed to overcome the thermal expansion and contraction of components in a bolted joint.

View full case study

Flange gasket leaked on a Y-Strainer at a steam plant for a local university. Several types of gaskets were used by plant personnel to attempt fix the leak. It was discovered by AP service reps that improper bolting and loading was the main cause of failure.

View full case study

Flange gaskets on coolant injection relay valve leaked at a Nuclear Power Plant. Original Vegetable Fiber Paper gaskets over-crushed easily and water wicked through the cellulose fibers. The use of Garlock Multi-Swell 3760 prevented leakage in this application.

View full case study

Gasket on Exciter Heat Exchanger blew out at Nuclear Power Plant. Corroded flanges were coated with Econ (epoxy), which created a smooth, uneven sealing surface. The gasket was replaced with Garlock Style 3760 Multi-Swell which worked well in this application.

View full case study

Some M & K Valves on fire protection systems have an anti-tamper switch depression on the valve stem causing graphite packing to fail if used. Additionally, a weak gland design limits the amount of packing stress that can be used, and typically this amount is less than the recommended stress for graphite packing.

View full case study

A nuclear plant in Illinois experienced a gasket leak from the water side of a hydrogen cooler flange. Existing gasket was a reinforced rubber gasket. The gasket was replaced with a Gore Power Grade gasket that resulted in no leaks.

View full case study

The 1.5”, Class 1500, Fig # 6981 Tandem Yarway blowdown valves have been very difficult to seal in the past. Large stuffing box configuration creates excessive packing friction and proper packing consolidation is very difficult to achieve resulting in a loss of radial packing load during plant operation.

View full case study

Packing leaks on a 54 Inch Chapman Motor Operated Gate Valve for the condenser inlet waterbox commonly occurred due to excessive in-service consolidation caused by the large valve stroke and improper packing selection. AP Services, after investigating the causes of valve packing leakage on these valves, designed a new packing set along with proper installation technique that eliminated leakage on these valves.

View full case study

Amertap condenser cleaning systems have a direct effect on the thermal efficiency of your plant. The horizontal quarter-turn stem configurations with small Limitorque actuators make traditional graphite ribbon packing a suboptimal sealing solution. The higher gland loads required to seal with graphite ribbon packing can cause an Amertap screen to fail to rotate.

View full case study

Gasket failed on a Heater Drain Tank Barrel Flange at a nuclear plant. The flange is subjected to temperature cycling and vibration. It was discovered that there was insufficient load for the spiral wound gasket used at the time of failure. Gasket was replaced with a flexible graphite Hochdruck (Style 6500) sheet material. The ability to seal at lower bolt loads than spiral wound gaskets along with the excellent sealability of Hockdruck graphite sheet proved to be a good choice for this application.

View full case study

Oil Leaks on flanges for the Hydrogen Seal Oil for the generator were common at a nuclear plant. The use of Garlock Multi-Swell 3760 gasket sheet proved to be successful solution in this application.

View full case study

Gasket failure occurred on a Moisture Separator Drain Tank Flange at nuclear power plant. The combination of imperfect flange surfaces, high vibration, and insufficient load for the spiral wound gasket were main contributors to the failure. Style 6500 flexible graphite sheet provided a gasket that conformed very well to flange surface imperfections and sealed at a lower bolt load than spiral wound gaskets.

View full case study

Metal fragments found in the steam generator at a nuclear plant. The fragments were determined to come from the metal winding in the spiral wound gasket used on the steam generator. The gaskets were replaced with a Kammprofile style gasket which consists of a solid metal core with graphite facing.

View full case study

A spiral wound gasket used on the turbine crossover flange buckled creating foreign material in the turbine. Gasket was replaced with a Kammprofile design which isn’t susceptible to buckling.

View full case study

Rubber skirting for a slurry feed box on a conveyor line at a coal fired power plant experienced tearing and failure within 24 hours of installation. The skirt material was upgraded to stronger cloth inserted neoprene with redesigned mounting points for better support.

View full case study

A customer was using a refrigerant grade neoprene gasket on the bell end for a chiller containing Freon-22. The Neoprene gaskets were failing in service.

View full case study

During disassembly of a 10 inch globe valve at a nuclear plant in Alabama, craft noticed that the spiral wound gasket for the body to bonnet joint had radially buckled and gasket material was found inside the body, creating an FME hazard.

View full case study

Original paper-like gaskets installed on copper piping flanges on the Stator Water Cooling system leaked in service at nuclear plant in New York. When leakage occurs in this system, the rectifier needs to be isolated to complete repairs. The gaskets were replaced with Garlock Multi-Swell 3760 and proved successful.

View full case study

A vegetable fiber gasket on the drywell sump pump flanges failed. The gasket was replaced with a Garlock Multi-swell 3760 gasket that eliminated leakage.

View full case study

A common problem in valve packing and other bolted connections is failure to address bolting conditions and their effect on packing and gasket performance.

View full case study

Inadequate and non-uniform loading on a gasketed joint is one of the most common reasons for gasket failure. One reason is due to nut/bolt head embedment into the flange bearing surface during the torque process.

View full case study

The Barrel Exhaust gaskets on the Diesel Generators at a Nuclear Plant experienced leakage.

View full case study

Chronic leakage occurred on the Emergency Diesel Generator at the Jacket Water Jumper flanges at a Nuclear Plant. Original gasket was a compressed fiber gasket. Very low bolt load availability makes it very difficult to achieve proper gasket load on this application.

View full case study

One challenge of installing gaskets is fitting the gasket in place on flat faced flanges. This is especially difficult on vertical positioned flanges where there are no bolt holes to help center the gasket on the flange.

View full case study

Carbon bushings can be susceptible to cracking if placed directly over a stuffing box bottom that is tapered.

View full case study

Existing Neoprene coupling gaskets on coal piping at a power plant were hardening and failing in service.

View full case study

Time, material waste, and manpower were greatly reduced by using Gore ePTFE Series Tape on the Bearing Thrust Housing Flange at a Hydro Electric Station in Pennsylvania.

View full case study

A rubber expansion joint prematurely failed at a plant due to off-set piping resulting in excessive over-stretching of the joint.

View full case study

Fabric Flue Duct Joints can fail prematurely due to the movement and stresses on HVAC Ventilation systems. They are also difficult to install / align. Garlock Style 8400 Expansion Joints installed in this system provide very long life and dependability.

View full case study

To request for more information click here