Chronic Valve Packing Leaks on 54 Inch Chapman Gate Valves on the Condenser Inlet Waterbox - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Chronic Valve Packing Leaks on 54 Inch Chapman Gate Valves on the Condenser Inlet Waterbox

Problem

The 54” Chapman Motor operated Gate Valve on the Condenser Inlet Waterbox has always been an issue to seal due to its large cross section packing and not being able to consolidate properly. The valve also has extremely long stem travel which makes it hard to prevent in service consolidation. The old style packing AP Services encountered when inspecting was a hard asbestos, graphite mixture. The packing was not consolidated and the tolerances of the packing were loose on the stem. Also, the packing rings were not staggered at 90 degrees.

Solution

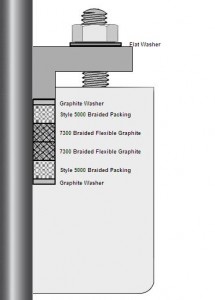

AP Services, after inspecting the valve, realized the issues and repacked the valve with a much softer packing which made it easier to consolidate. One ring of Style 5000 on the top, two rings of 7300 in the middle and a Style 5000 ring on the bottom. Also, a Style 6200N graphite washer was installed on the top and bottom of the set to ensure the braided style 5000 would not skirt, and the packing set would have reduced friction along with longer life. This designed set created a much better seal. Three rings were put in the valve then the valve was torqued to consolidate the packing and then the 4th ring was placed in and the process continued until no consolidation was left in the packing set. 17-7 hardened flat washers were also used on this valve to keep the nuts from cutting into the follower and reduce friction thus creating a more accurate torque. At one site alone this set has been packed in 18 valves with 100% leak free operation.