Diesel Generator Jacket Water Jumper Gaskets - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

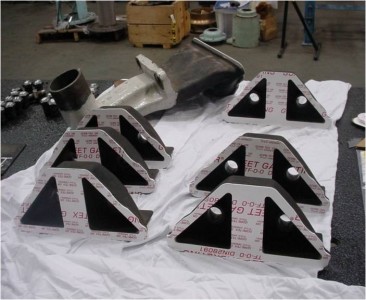

Diesel Generator Jacket Water Jumper Gaskets

Problem

Chronic leakage occurred on the Emergency Diesel Generator at the Jacket Water Jumper flanges at a Nuclear Plant. Original gasket was a compressed fiber gasket. Very low bolt load availability makes it very difficult to achieve proper gasket load on this application. The gaskets have to be glued in place so that the covers can be installed.

Solution

The solution was to change the material to Gore-Tex Power Grade ePTFE. Gore Power Grade is a soft, compressible material that forms a tight seal under lighter bolt loads as compared to harder compressed fiber gaskets that require higher bolt loads to seal. The gasket was provided with a double faced tape on one side to keep the gasket in proper position on the flange face until the cover was installed. No leakage has been present since the upgrade of this material.