Super Critical Turbine Flanges Leak due to Oxidation of Graphite Gaskets - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Super Critical Turbine Flanges Leak due to Oxidation of Graphite Gaskets

Problem

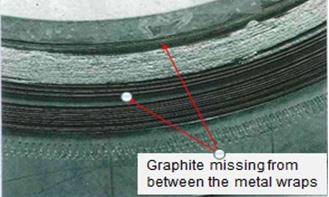

Accelerated oxidation of graphite can occur above 650 degrees F, which leads to severe steam leaks.

The PVRC HALR Test on confined flexible graphite gaskets confirms that oxidation affects graphite filled spiral wound gaskets, at temperatures much lower than anticipated. Oxidation has been evident on spiral wound gaskets used in steam extraction valves and other applications in steam service. Expected Service Life of Flexible Graphite Sheet Gaskets:

- 5 years @ 610°F

- 3 years @ 660°F

- 1 year @ 691°F

Solution

The replacement of graphite with a Thermiculite faced Kammprofile gasket or a Thermiculite filled spiral wound type gasket has eliminated these leaks. Oxidation of Flexible Graphite is a major concern in sheet gaskets and spiral wounds at temperatures greater than 600 degrees F. Thermiculite maintains its integrity up to 1800 degrees F.