Maximizing Amertap Quarter-Turn MOV Efficiency - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Maximizing Amertap Quarter-Turn MOV Efficiency

Problem

Amertap condenser cleaning systems have a direct effect on the thermal efficiency of your plant. The horizontal quarter-turn stem configurations with small Limitorque actuators make traditional graphite ribbon packing a suboptimal sealing solution. The higher gland loads required to seal with graphite ribbon packing can cause an Amertap screen to fail to rotate. A low-friction, high-sealability braided packing set will allow Amertap screens to rotate as designed and increase the cleaning efficiency of the system.

Solution

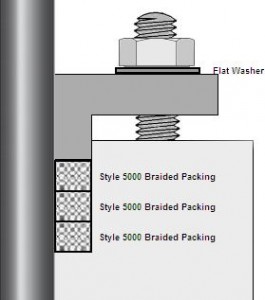

Die-formed AP Style 5000 ring sets provide the optimal sealing solution of high sealability and low friction at low gland stress. Due to the low system pressure in Amertaps 2500 psi packing stress is preferred. During installation make sure to compress each ring individually as traditional packing consolidation techniques do not work in quarter-turn applications. Installing the optimal sealing solution in your Amertap condenser MOVs can have a direct effect on the power output of your plant.

Note: Stuffing box dimensions and stud sizes are typically metric. Allow AP Services to individually die-form these rings to help the installation process and avoid installing over- or under-sized bulk packing.