Flange Gasket Leak in High Cycling Heat Exchanger - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Flange Gasket Leak in High Cycling Heat Exchanger

Problem

The gasket in service was a Kammprofile. Unfortunately, this gasket did not offer enough sufficient recovery to compensate for the drastic changes in temperature and pressure. The system cycles up and down twice per day: 35 deg C to 220 deg C. It can see a max temperature and pressure of 291 deg C and 7500 kPag. The speed of the cycling can be 35 deg C to 180 deg C in 5 minutes.

Solution

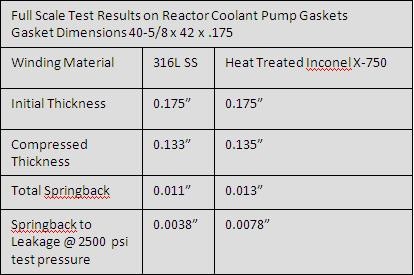

AP Services offered transitioning from a Kammprofile to a Flexitallic Style RIR. The winding material offered was heat treated Inconel X-750. The flanges were male/female and open on the ID. The RIR was used to prevent over compression and to avoid any FME issues that may have resulted from a style R. The excellent recovery properties of the heat treated Inconel X-750 resulted in a leak free seal and significantly increased the service life of the gasket.