Corroded Eyebolt Studs Lead to Poor Packing Performance - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Corroded Eyebolt Studs Lead to Poor Packing Performance

Problem

A common problem in valve packing and other bolted connections is failure to address bolting conditions and their effect on packing and gasket performance.

Solution

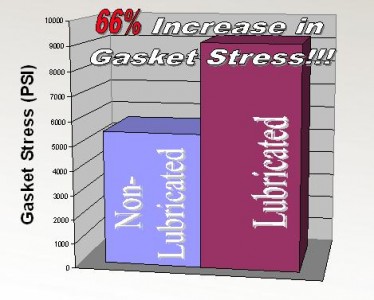

Proper packing stress or gasket load must be exerted onto the component in order to achieve acceptable sealing performance. A stud/bolt that is rusted or corroded will significantly decrease the amount of load transfer to the packing or gasket seal due to the considerable amount of friction the nut has to overcome on the threads. Many tests have shown that a lubricated stud in good condition will generate around 50% more load as compared to an unlubricated or rusty stud.

Bolts/studs should be replaced or cleaned and chased, well lubricated, and hard washers installed under the nuts to minimize friction between the nut and bearing surface. The nut faces should also be lubricated.