Improve Gasket Performance with Hardened Steel Washers - SealOE

Brands - AP Services

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Improve Gasket Performance with Hardened Steel Washers

Problem

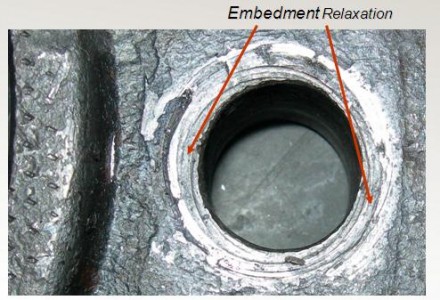

Inadequate and non-uniform loading on a gasketed joint is one of the most common reasons for gasket failure. One reason is due to nut/bolt head embedment into the flange bearing surface during the torque process. Embedment leads to relaxation or creep and increases the friction at the bearing surface of the turned element. The end result is a lack of or loss of critical gasket stress.

Solution

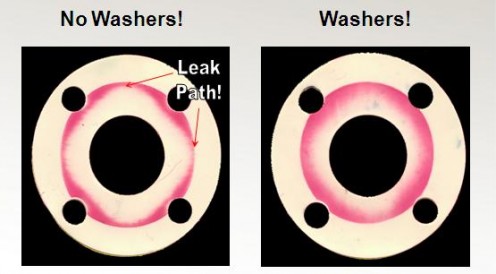

One method to improve and help ensure proper bolt load is distributed to the gasket area is to install hardened flat washers under the bolt heads or nuts. Testing has shown that the use of hardened washers can increase gasket load 30-50% more than without the use of washers. Other benefits of this simple addition to a bolted joint connection are:

- Distributes the load more evenly and uniformly over flange face

- Prevents surface damage and embedment

- Reduces friction at the bearing surface

- Compensates for irregular surface conditions