Gas Turbine Bearing Oil Drain Flange Gasket - SealOE

Brands - AP Services

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Gas Turbine Bearing Oil Drain Flange Gasket

Problem

At the #2 Bearing Oil Drain flange, hot air at 700°F and 180 psi pressure blew out a simple flexible graphite sheet gasket. Change out is extremely difficult, costly and time consuming (6 days). To replace a conventional one piece gasket, an outside contractor needs to remove components, and drain and store 3300 gallons of oil. At least one plant has welded the joint shut, not realizing there was a solution.

Solution

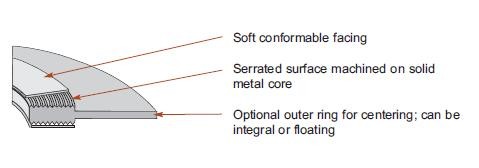

Flexitallic worked with customer to design a special segmented Flexpro kammprofile style gasket. The benefits of this style gasket include:

- Quicker installation; 6 hours instead of 6 days

- Quiker return to production

- In-house labor instead of outside contractors

- A more robust, blowout resistant gasket with metal core

- Cost savings of $15,000