Valve Packing Leaks on 1.5 Inch Class 1500 Tandem Yarway Blowdown Valves - SealOE

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Valve Packing Leaks on 1.5 Inch Class 1500 Tandem Yarway Blowdown Valves

Problem

The 1.5”, Class 1500, Fig # 6981 Tandem Yarway blowdown valves have been very difficult to seal in the past. The 0.937” stem and the large stuffing box creates too much friction for the packing. The old style (eight rings of graphite and yarn) packing that was used could not consolidate all the way through evenly and would eventually bottom out the gland. These valves need to be operable at all times. Also, with the high torques used, the face of the gland follower was being cut by the nut.

Solution

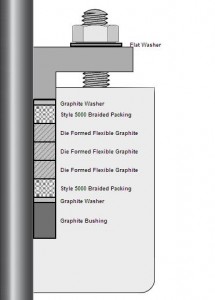

The solution to this problem was to lower the amount of rings from eight to five and also add two graphite washers on the outside of the yarn to reduce skirting, friction, and wear on the packing. We also added a Style 5010 high density carbon bushing to take up the rest of the space in the stuffing box and realign the stem since the valve is horizontal positioned. AP Services techs put the high density bushing, graphite washer and the first four rings of packing in, consolidate completely then add the 5th ring, torque accordingly and re-stroke a minimum of 5 times or until the consolidation is complete. 17-7 Hardened Flat Washers were also installed below the gland nuts to reduce friction on the nut and gland follower and to ensure correct torque was met. The valves were also taken apart and inspected to make sure the valves weren’t clogged from debris. At one site alone AP Services has repacked 144 of these valves with 100% leak free operation.