Address Limited Stuffing Box Height and/or Lower Friction Requirements for a Graphite Packing System - SealOE

Brands - AP Services

HOME | BRANDS | AP Services | sealOE™ | Case Studies Details

Address Limited Stuffing Box Height and/or Lower Friction Requirements for a Graphite Packing System

Problem

Typically in the new standard 5 ring stuffing box design, it is not possible to include packing system improvements such as graphite washers or tight tolerance carbon bushings due to the stuffing box depth.

Solution

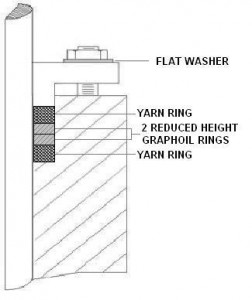

Only one die formed sealing ring is required to seal, but standard practice is to install at least 2 packing die formed graphite sealing rings. The use of 2 reduced height rings provides a viable, field tested solution to this issue.

A typical example is at PPL Susquehanna’s 28” A&M MSIV globe valves. To insure that stem scoring was prevented, tight tolerance carbon bushings were desired on the top and bottom. By using on 2 reduced die formed rings, the carbon bushings could be added to the packing set.