CWNC

Curtiss-Wright Nuclear Canada (CWNC)

Located in Newmarket, Ontario, Curtiss-Wright Nuclear Canada (CWNC) is a product and service brand of Curtiss-Wright Nuclear, providing seismic qualification, commercial grade dedication, equipment qualification, and project management services to support the local Canadian nuclear market and the international fleet of CANDU utilities. CWNC’s services include seismic testing and analysis, radiation testing, and thermal aging, as well as safety-related repair, refurbishment, and reverse engineering to extend the life of electrical and mechanical components. Additionally, CWNC manufactures a portfolio of conductivity cells and cell holders.

Products and Services

Click the links below to learn about CWNC's products and services. For more information, download our brochure.

CWNC is certified by the TSSA to CSA N285 and CSA B51 for fabrication of welded and non-welded components. We design, certify, register, and perform qualification tests for pressure boundary pumps and fittings.

- CSA Standard B51 Boiler, Pressure Vessel and Pressure Piping Code

- Fabrication of Welded and Non-Welded Category A, B, C, F and H type

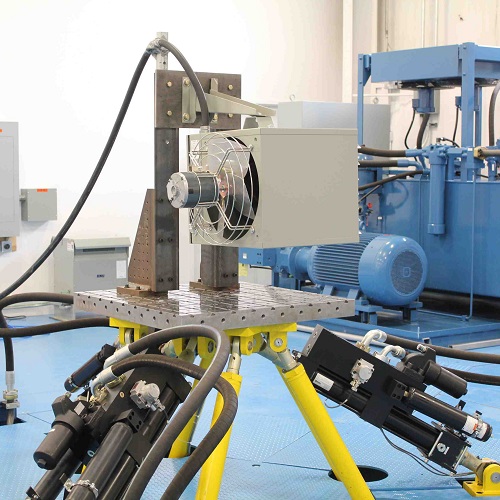

- Seismic Testing and Analysis, including a tri-axial table with:

- 3ft x 3ft tri-axial t-slotted shaker with 10,000 lb capacity

- 10-inch stroke actuators

- 160,000 ft-lb overturn capacity

- Random, sine-sweep, sine-beats, continuous sine-wave or white noise excitation

- Capability to hit up to 30 g Seismic Levels

- Frequencies of up to 100Hz

- Consistent with CSA N299.1 series requirements, and the IEEE 344 and IEEE 323 standards

Curtiss-Wright Nuclear Canada offers seismic testing service from conception to completion:

- Procedure Preparation

- Custom test specimen fixturing

- Custom test specimen monitoring

- Reporting

As one of the testing facilities for the EPRI SQURTS program, we offer industry-recognized seismic qualification for EPRI members.

The CWNC facility offers a comprehensive set of equipment qualification capabilities no matter what the requirements:

- Harsh and Mild Environments (High Temperature and High Humidity Testing)

- LOCA (Loss of Coolant Accident) Testing

- Thermal and Mechanical Aging

- Radiation Services

- Gamma Radiation Qualification

- Electromagnetic Interference/Compatibility Testing (EMI/EMC)

- Software Qualification to CSA N290-14

- Testing Facility for the EPRI SQURTS Program

All of the above can be completed individually depending on component and project requirements. CWNC completes this testing from conception and development to completion and qualification.

CWNC has the historical data, knowledge, and experience to assist with the qualification of commercial grade items for use in nuclear safety-related applications.

Our methodology begins with a dedication procedure that includes:

- Full Services Commercial Grade Dedication (CGD) Services

We offer an exhaustive suite of CGD services that cover every aspect of the qualification process, from item identification and critical characteristic determination to sourcing, testing, and final documentation, ensuring that each component meets the exacting standards of nuclear safety and reliability.

- Reverse Engineering and Refurbishment Services, Including Obsolescence Solutions

Our expertise extends to reverse engineering and refurbishing essential components, particularly when faced with the challenge of obsolete parts. By precisely replicating and enhancing original designs, we provide sustainable solutions that extend the lifespan and improve the performance of nuclear reactors, specializing in CANDU reactors.

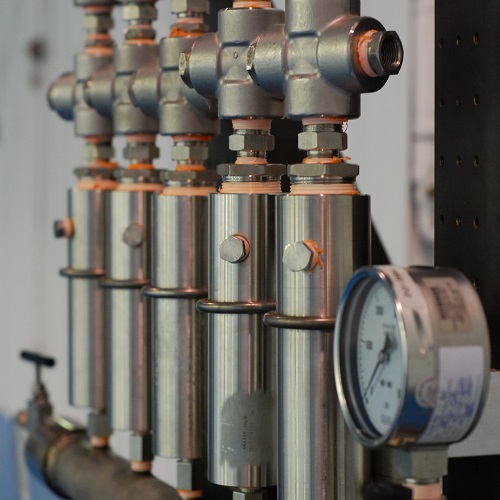

- Pressure Boundary Engineered Components

Specializing in the engineering and supply of pressure boundary components, we adhere to the highest standards, ensuring compliance with TSSA to N285, and CSA B51 standards, crucial for maintaining the integrity of reactor pressure boundaries.

- Conductivity Cells and Cell holders

Our conductivity cells and cell holders are meticulously designed and certified to meet the rigorous requirements of TSSA to N285, N299 and CSA B51 standards, demonstrating our commitment to providing high-quality, reliable components for CANDU reactors.

Our in-house test facilities contain the fundamental equipment necessary in completing commercial grade dedication in an effective and timely manner.

CWNC is certified by the TSSA to CSA N285 and CSA B51 for fabrication of welded and non-welded components. We design, certify, register, and perform qualification tests for pressure boundary pumps and fittings.

- CSA Standard B51 Boiler, Pressure Vessel and Pressure Piping Code

- Fabrication of Welded and Non-Welded Category A, B, C, F and H type

- CSA Standard N285.0 General Requirements for Pressure Retaining Systems and Components in CANDU Nuclear Power Plants

- Fabrication of Class 1, 2 and 3 Welded Non-Welded Category F and H type Fittings

- Construction of Class 2 and 3 Pumps, Class 2 and 3 Shop Assembly

We also offer a portfolio of conductivity cells, cell holders, and digital conductivity analyzers, which are manufactured at our Newmarket facility. In conjunction with conductivity cells we can also offer a range.

Curtiss-Wright develops environmentally qualified systems and hardware solutions with an experienced project management team that supports the supply of safe, reliable, and economical electricity with extensive experience in the nuclear industry, CWNC’s team of project management professionals assist in the successful completion of projects on budget and on time.

Curtiss-Wright maintains relationships with qualified teaming partners to upgrade commercial products, including:

- Eaton

- York Chiller Parts - Johnson Controls

- Penny & Giles – Potentiometers

- Schweitzer Engineering Laboratories (SEL)

- HVAC Systems and Safety Related Chillers

- Solar Turbines

Utilizing resources from across Curtiss-Wright, CWNC can reverse engineer, refurbish, and provide obsolescence solutions for a wide variety of mechanical, electrical, and electronic components in both safety related and commercial applications. We design and manufacture exact replicas to ensure that all replacement components strictly adhere to the fit, form, and function of the original.

CWNC’s qualification center is fully equipped to perform testing in-house on a broad range of components and assemblies, and has been designated as a testing facility for the EPRI SQURTS program. Their tri-axial shaker table has a 10,000 lb. capacity and can be accelerated to 30 g with frequencies of 100Hz. All seismic testing and analysis is consistent with the requirements of the CSA N289 series, the IEEE 344 standard, and the IEEE 323 standard.

CWNC’s quality assurance program is NUPIC-audited, meeting both the CSA N299.1-2016 and 10CFR50 Appendix B requirements for Canada and the United States. CWNC is also certified by TSSA to N 285 and CSA B51 for fabrication of welded and non-welded components, as well as the construction of pumps.