FAMOS Monitoring Software: Customer Success Stories

July 28, 2023

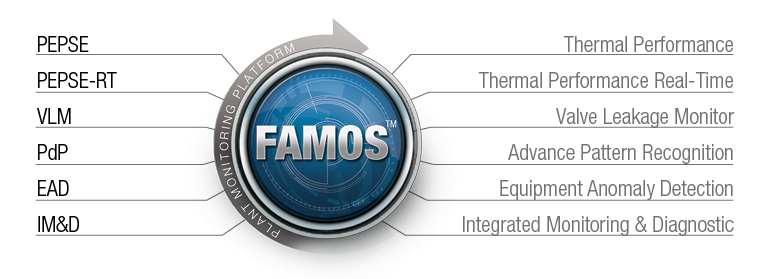

Curtiss-Wright’s Fleet Asset Management Optimization Solutions (FAMOS) monitoring software incorporates machine learning and advanced algorithms to identify issues before they can become failures in conventional and nuclear power plants. FAMOS uses advanced software to identify and analyze anomalies from a multitude of real-time sensor readings, minimizing the risk of failure.

FAMOS is a stable multi-faceted monitoring platform built on best-in-class plant process computing technology to optimize data management and simplify the addition of more data points as plants add more sensors and digital processes. The versatility of the platform for plant monitoring exemplifies the ‘digital twin’ approach using first-principle physics models to accurately represent the plant and combines advanced analytics to give plant customers and stakeholders real-time feedback of plant performance, equipment degradation, and diagnostics.

The effectiveness of the FAMOS monitoring platform is the software architecture, which leverages decades of Curtiss-Wright data management technology for plant process computer application. Customers are recognizing the value of the platform to expand monitoring, including adding wireless sensor information. Currently, a pilot is underway to show how FAMOS simplifies the addition of temperature sensors for a U.S Nuclear Fleet customer to assess the effectiveness of increasing the number of monitoring data points and take advantage of lower wireless implementation costs. The following are two recent FAMOS monitoring customer successes:

(A) U.S. Nuclear Fleet customer using the PEPSE-RT (thermal performance) & VLM (valve leakage monitoring) tools within FAMOS. These FAMOS tools are currently used by the Fleet Thermal Performance Engineer to monitor multiple nuclear power units. The application of both thermal performance and valve performance has increased the awareness of lost generation and efficiency degradation and provided a centralized, comprehensive system for assessment of fleet performance. Recently after returning to service after a maintenance shutdown, the system identified an open steam bypass valve having a substantially negative effect on megawatt production.

(B) U.S. Nuclear Fleet customer using FAMOS PdP (advanced pattern recognition) as part of developing their central M&D center to optimize asset condition monitoring and maintenance practices. The outcome from using PdP resulted in the following:

-

Identification of faulty sensors, and

-

Early detection of equipment degradation such as bearing failures.