Service Life Extension of Legacy Brand Valve and HVAC Damper Actuators

March 26, 2018

With over 50 years of experience in the nuclear power industry, Curtiss-Wright Nuclear has a deep understanding of the obsolescence challenges facing plants today.

Generation II commercial nuclear plants that obtain License Renewal face a challenge – service life extension of legacy brand gas-hydraulic valve and HVAC damper actuators. Valve and damper controls are subject to equipment aging and wear. Diligent condition monitoring is a critical task.

Supporting obsolete actuator designs for the duration of a 20-year license renewal period carries a unique set of difficulties. Many safety-related and commercial grade sub-component suppliers from the 1970s have ceased production of Class IE motors, directional control solenoids, reporting instruments, and other critical sub-components – leaving nuclear plants unable to source qualified and commercial grade parts for planned and unplanned maintenance. In addition to the limited availability of materials needed to achieve equipment reliability objectives over the next two decades, there is a lack of OEM technical support due to equipment vintage and product obsolescence.

The primary goal in actuator service life extension is to reduce maintenance frequency while improving reliability. “Delivering the Nuclear Promise”, a nuclear industry initiative aimed at increasing efficiency and safety, underpins this objective

There are different methods to solve this particular obsolescence problem – namely, substitution and design change.

Parts Substitution: Replacement parts must have equivalent mechanical and performance characteristics; equivalent environmental qualification; and assured long-term availability. Component upgrade solutions provide access to qualified spare parts and technical support availability with minimal design change engineering and installation costs.

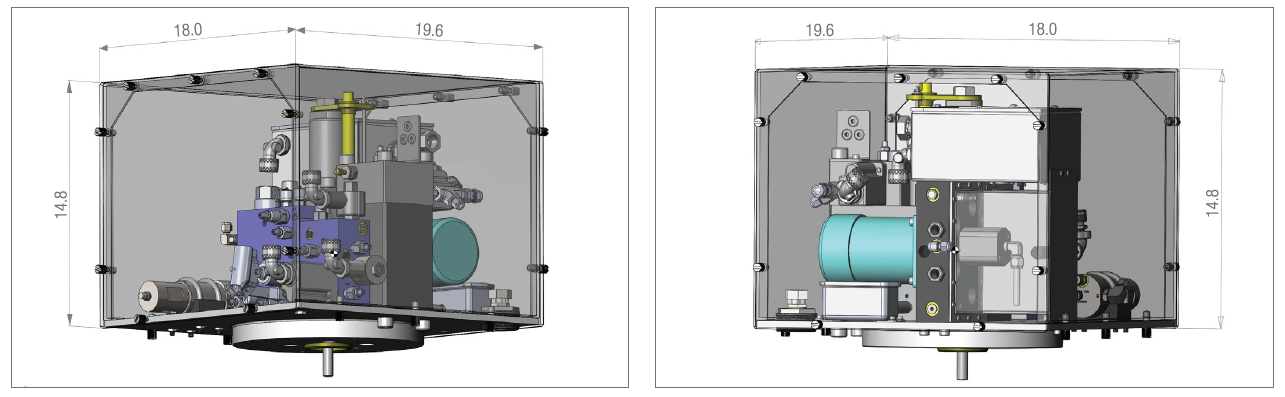

Actuator Design Change: When implementing design change for a legacy brand actuator, there must be a minimal (<10%) impact to the overall assembly weight and Cg, and the replacement actuator should have no impact on the power consumption or assembly performance. Replacement actuators offer extended maintenance cycles, resulting in less frequent maintenance work.

Curtiss-Wright Nuclear specializes in design and material support for legacy brand gas-hydraulic actuators used in safe plant shutdown application. We provide long term technical and material support for obsolete equipment to assure reliable plant performance while meeting Nuclear Promise objectives. Our material support program offers qualified spare parts and technical support for a wide range of legacy product brands, while our replacement actuators feature equivalent configuration and performance; design compactness; and improved reliability with EQ service intervals of up to 14 years for maintenance cost reduction. Contact us to learn more about our obsolescence solutions.

Contact

Julio Adame

714.982.1888