Anatec

HOME | BRANDS | Scientech | Outage and Fuel Management | Anatec

Anatec

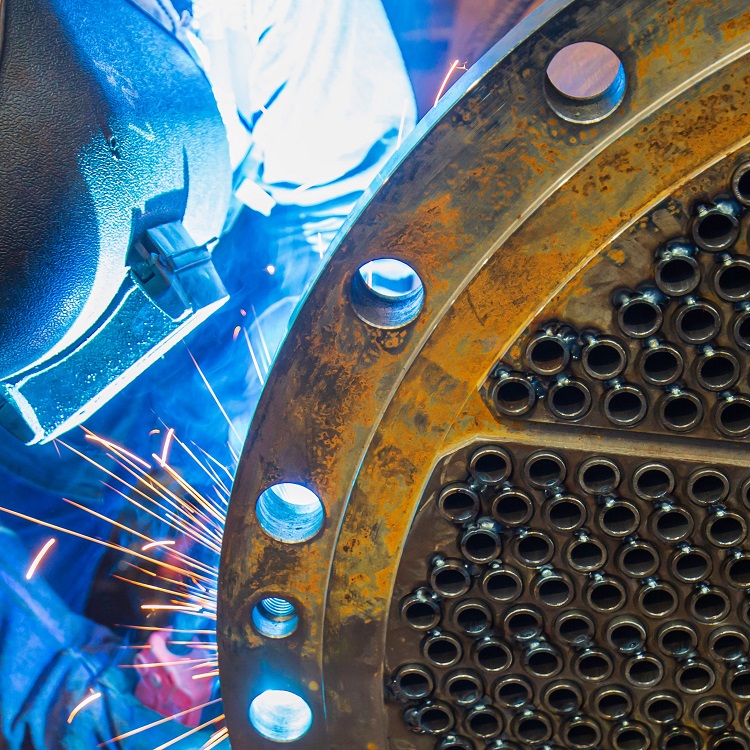

Curtiss-Wright's Anatec business unit is a leading provider of Electromagnetic Testing (ET) Services to the Nuclear, Oil & Gas, Industrial, and Defense markets. Founded in 1983, Anatec continues to build upon Glenn Curtiss and the Wright brothers' legacy of innovation providing quality service and technology coupled with subject matter experts in the field of advanced ET services. Our skilled and experienced team utilize the latest techniques and technologies to provide customers with reliable, innovative solutions for critical challenges.

NDE / NDT Testing and Services

Click the links below to learn about the following Anatec services:

Curtiss-Wright provides Advanced Electromagnetic Testing services to the oil & gas, nuclear, and other industries. Our team of experts develops and delivers the latest technology, equipment, procedures, and programs to help ensure continued safe operation, equipment reliability, and regulatory compliance across multiple industries. Our highly skilled and experienced technicians utilize the latest in Advanced Electromagnetic Testing (AET) to provide customers with innovative solutions for technically challenging and critical situations. Our specializations include:

- Surface Eddy Current (Array Capable)

- ECT surface weld testing - single probe or array probes

- Flexible array probes for challenging or complex geometry inspections

- Alternating Current Field Measurement (ACFM)

- Accurate depth sizing in ferrous material

- Anticipated flaws with depths greater than .250’’

- Best for thoroughly examining coating, saving on abatement and recoating

- Random, sine-sweep, sine-beats, continuous sine-wave or white noise excitation

- Array capable of crack detection and sizing for greater coverage faster

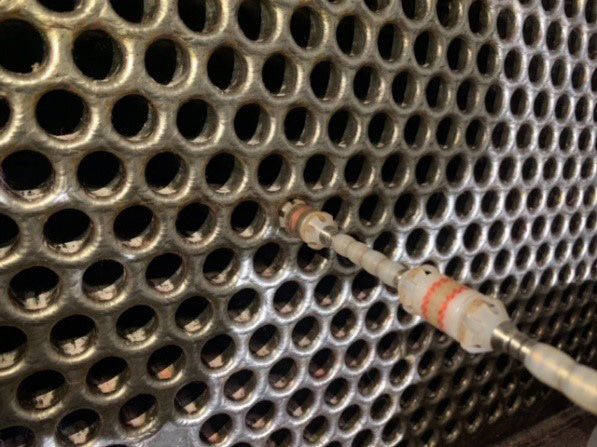

- HX Condition Assessment, including Conventional and Specialized Tubing Examinations

- Damage Mechanism Identification, Quantification, and Possible Corrective Action Development

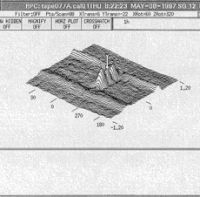

- 3-D Modeling of Damage Areas for HX, Piping, and Vessels

- Pulsed Eddy Current (PEC) Testing

- Remote Field Testing in Ferrous Material

- Boiler Tubing Applications

- Specialty Alloy (Duplex, Monel, Nickle 200 Applications)

- Remote Field Testing in Ferrous Material

- Array Probe Techniques

- Tube Plugging and Stabilization Services

Curtiss-Wright’s electromagnetic testing personnel have extensive experience in the delivery of BOP heat exchanger and condenser ET services. We specialize in HX Condition Assessment, identifying and quantifying damage mechanisms and possible corrective actions, 3- D modeling of damage areas, and specialty applications such as Incore Thimble Tube inspection and condenser steam side visual inspections. Our array probe technology, utilized for flaw characterization, enables specific corrective measures and determination of remaining useful life of a component. Through a partnership within Curtiss-Wright, we can also provide tube plugging and stabilization services.

We offer innovative remote controlled robotic technology for use in high radiation dose and/or contamination environments. This system has been deployed on several of our projects, resulting in substantial reduction in personnel radiation exposure.

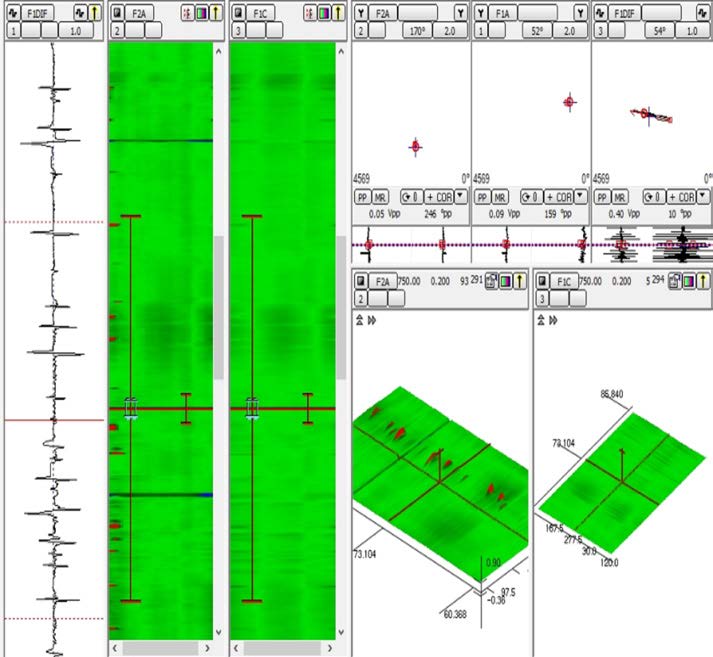

Curtiss-Wright's data analysis services are built to be user-friendly on every level: they can be performed on a variety of analysis software platforms, and remote analysis can be performed, minimizing travel and site training costs. Remote analysis over T-1 or VPN network connections has been performed for both domestic US and international clients. Our data management personnel are also proficient in the use of many data management software offerings - our data acquisition specialists have worked with nearly every remote delivery system in use in the US, as well as performed repair functions (tube plugging and sleeving) and equipment maintenance.

In addition to our analysis services, our commitment to personnel training and development, our participation in industry committees and working groups, and our involvement with Code and regulatory bodies allows us to provide our customers with superior inspection and oversight personnel. Several of our Level III personnel function as independent Qualified Data Analysts (IQDA) or as contracted Utility Level III. In each of these cases, the personnel are responsible for oversight of the entire inspection program. Curtiss-Wright's Anatec group also offers:

- Auto Analysis Software

- IM-2 Manipulator System

- SG Eddy Current Testing Independent Data Analysis

ET knowledge transfer is a key capability for our organization. We provide fundamental and specialized training services for our clients in basics of eddy current testing, array probe testing, Qualified Data Analyst (QDA) training and Level III training and certification. We have also conducted Data Base Management training for our staff and clients. Specialized training on Advanced Electromagnetic Testing can be provided for Surface Array probe testing, Pulsed Eddy Current Testing and Remote Field and ACFM testing. Our team can provide tailored training services based on your unique needs and requirements.