FAMOS-DVR-RT

HOME | BRANDS | Scientech | Information Technologies |FAMOS | FAMOS-DVR

FAMOS-DVR

Quality-Assured Thermal Performance Monitoring

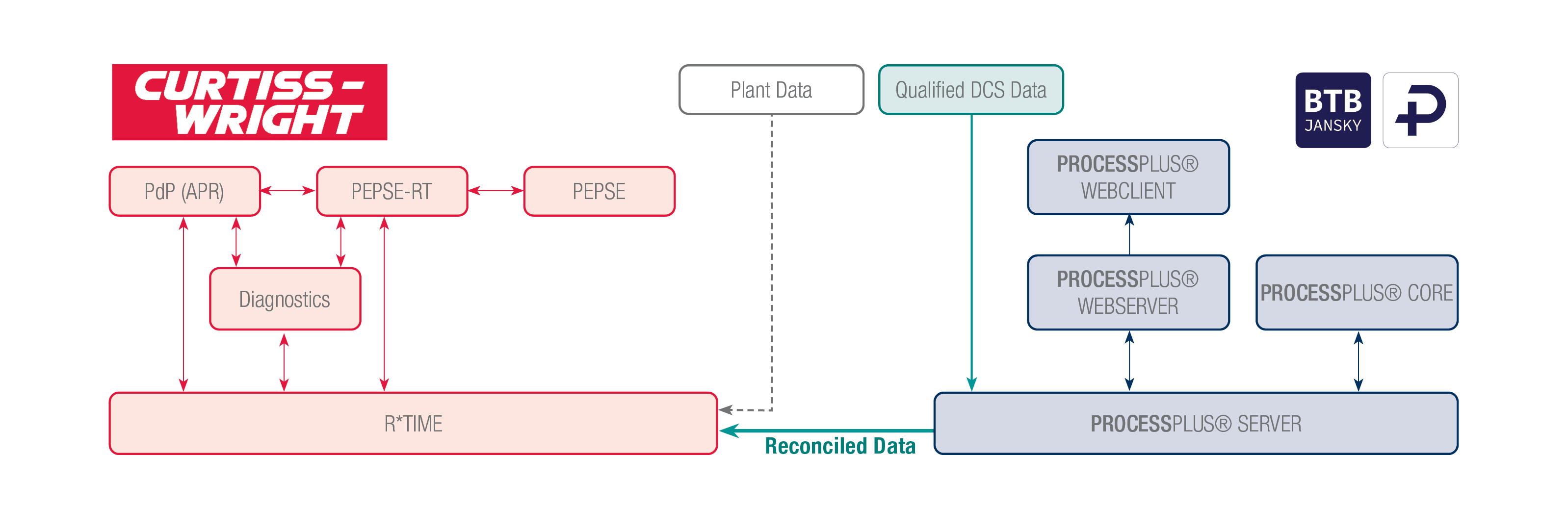

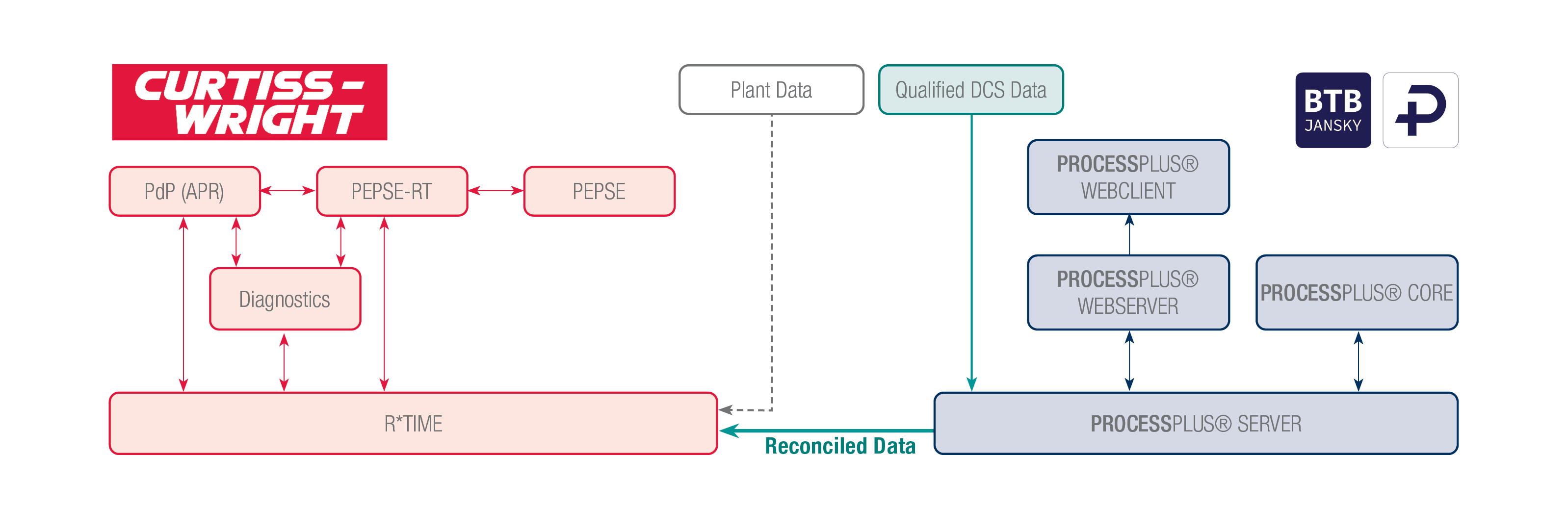

Curtiss-Wright has teamed up with BTB Jansky to bring their certified Data Validation & Reconciliation (DVR) tool, PROCESSPLUS®, into the FAMOS suite of solutions. This combination of PROCESSPLUS along with FAMOS tools and applications provide an enhanced on-line thermal performance monitoring by reconciling and validating quality-assured measurements. To date, PROCESSPLUS has been applied in over 70 power plants worldwide.

FAMOS (Fleet Asset Management and Optimization Solutions) is the suite of Curtiss-Wright products built on more than 40 years of power industry experience. Combining domain expertise with advanced technology, the FAMOS suite is an integrated solution tool set for monitoring equipment, detecting problems, analyzing anomalies, improving plant performance, and accessing vast amounts of plant data which are the foundation of your operation. These integrated applications provide an in-depth approach to plant performance monitoring and optimization.

The reconciliation software PROCESSPLUS is developed to solve the problem of erroneous input and is certified to VDI 2048 (2017). PROCESSPLUS is the first software system on the market certified according to the standard for process data reconciliation technology to deliver resilient, contradiction-free, and quality-assured process data—even for process areas which are unmeasured.

PROCESSPLUS® is a licensed product of BTB Jansky and has been applied to 70+ power plants including nuclear power (BWR, PWR, CANDU), coal-fired, CCGT, and gas power plants.

Benefits of FAMOS-DVR

FAMOS-DVR continuously produces process reference values in near real-time for the entire power plant. By providing plausible, contradiction-free, quality-assured process data, FAMOS-DVR provides a state-of-the-art monitoring system for nuclear power plants of all reactor types. Using reconciled data instead of raw measurements for plant operation results in increased plant safety, efficiency, electrical output, and ultimately, revenue.

- Generates contradiction-free (reconciled) plant data

- Power recovery with reconciled correction factors for feedwater flow and temperatures

- Increased reactor power accuracy and process measurement accuracy

- Instrument and core thermal power validation

- Reduced measurement uncertainty at 95% confidence interval

- Measurement uncertainty recapture (MUR)

- Detection of critical instrument drift

- Component monitoring with the possibility to extend maintenance intervals

- Measurement monitoring with the possibility to extend maintenance intervals

- Increased plant safety

- Identification/quantification of cycle isolation losses

- Quality-assured component performance monitoring

- Warranty and retrofit testing

For more details, please visit our dedicated FAMOS Suite website.

.

Related Documents

To request for more information click here